Corrugated Plastic started to be used as alternative for corrugated paper boxes in Europe in the late 1970’s. The United States began producing corrugated plastic in the mid 80’s. Polyethylene resin(PE) can be “welded” with a similar structure to corrugated fiberboard, but provides better performance.Plastic welding is welding for semi-finished plastic materials, and is described in ISO 472 as a process of uniting softened surfaces of materials, generally with the aid of heat (except solvent welding). Welding of thermoplastics is accomplished in three sequential stages, namely surface preparation, application of heat and pressure, and cooling.

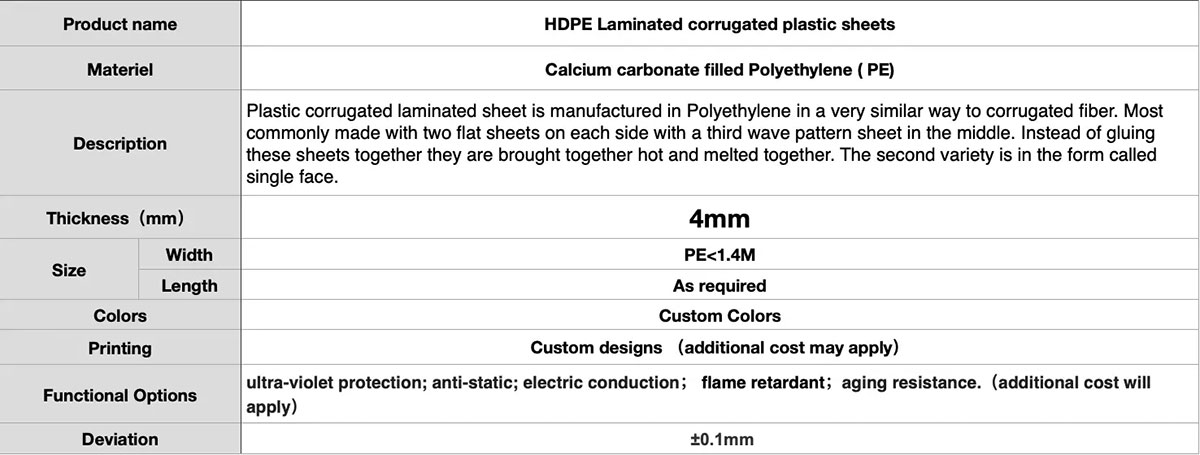

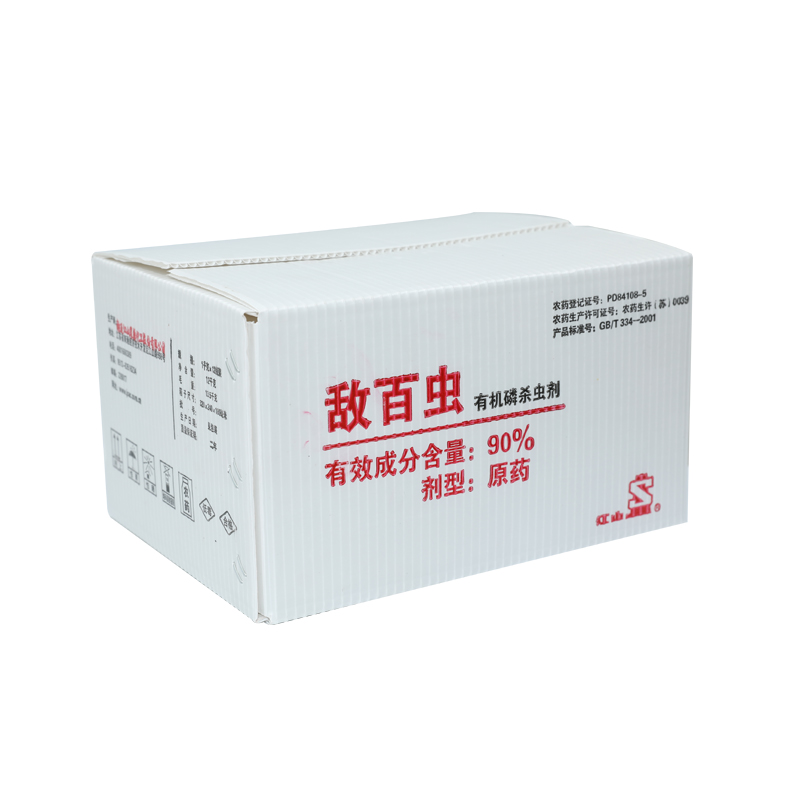

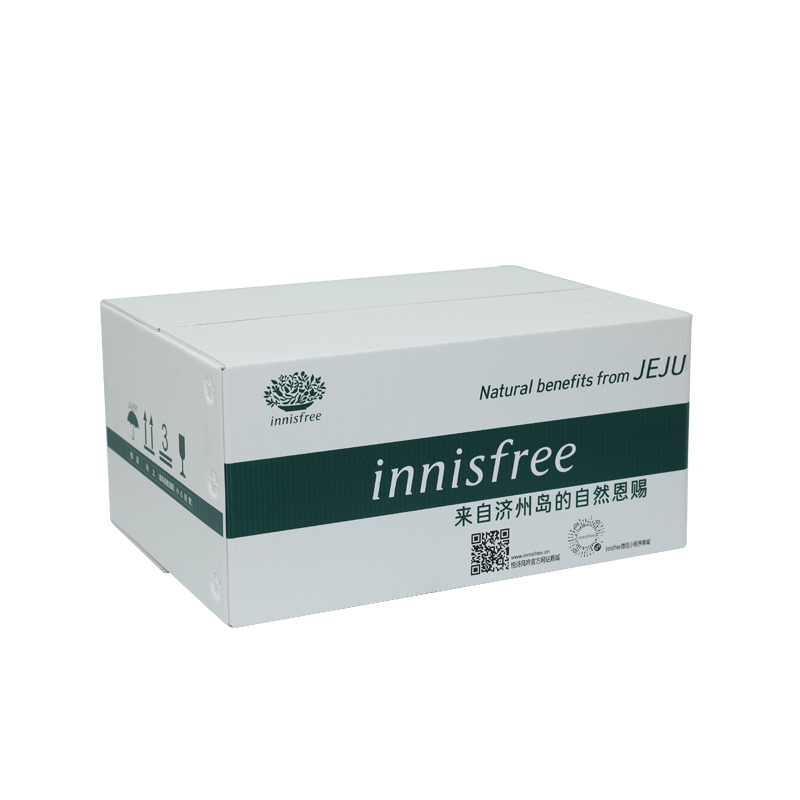

When producing containers or sheets in plastic corrugated laminated (Wave-Beam) structure it will always be made from polyethylene. The most common thickness for PE laminated (Wave-Beam) is 4mm. This material is widely used to commercial, political signs and for constructing plastic containers, reusable packaging, pet cages and so on.

Polypropylene vs Polyethylene Plastic Corrugated

Depending on how you are going to use your product. PE is less affected by extreme cold applications. When the temperatures reach 10℃ or lower PP will begin to have a tendency or at least more likely to fracture or crack when it takes an impact or when flexed or folded in this cold environment.

PE is also softer, so it may be selected or rejected for the project because of this factor. The warmer the environment the softer polyethylene will become.

PE plastic corrugated sheet more “shinning and smooth” than PP plastic corrugated sheet.

Both materials have their benefits and deficits. So each project needs to be evaluated before making a decision.

WHY US?

* Leading manufacturer with 20 years experiences

* Sold tens of millions of containers

* Professional team and services

* Top quality and attractive price

• Please note that all products will need to be manufactured at the time of order.

• The sizes, designs and colors might be different for each customer, so please let us know your requirements and circumstances it will be used, we will give appropriate suggestions based on our experience.

• It normally takes 1-2 weeks for manufacturing "standard"products since we receive deposit.

• For large quantity orders or complex printings and designs, please contact us for more details.

• To choose PP extruded profile material or HDPE Laminated material, It depends on the project and design of your product. Both materials have their benefits and some deficits.

A1: The minimum order quantity is 500 pieces. However it might not be cost-effective on postage for small orders.

A2: Of course, please note the transportation will be on your own cost and need to be paid in advance.

A3: We accept all OEM orders. Please contact us for more details.

A4: By T/T, 50% deposit in advance, balance 50% before shipment.

A5: We usually respond your inquiry within 24 hours. The sizes, designs and colors might be different for each customer, so please let us know your requirements and circumstances it will be used, we will give appropriate suggestions based on our experience and quote for you.